Case Study of the Headquarters and Factory Construction Project of Thermal Cube Technology (Foshan) Co., Ltd. - Ceramic Crystal Stone Engineering

2025/11/17

I. Project Overview

● Project Name : Headquarters Plant and Basement Construction Project of ThermoCube Technology (Foshan) Co., Ltd.

● Project Location : Shilong Industrial Zone, Lunjiao Subdistrict, Shunde District, Foshan City, Guangdong Province (east of Fulong Road and south of Junyi North Road)

● Construction Unit : ThermoCube Technology (Foshan) Co., Ltd.

● Building type : Modern intelligent manufacturing center (multi-story factory, office building, basement)

● Completion date : Fully delivered and put into use in 2024.

● Design style : Industrial modern, with classic warm beige and light gray as the main tones, showcasing a coexistence of technology and warmth.

● Paint supplier : Guangdong Yongrong New Building Materials Co., Ltd. (direct supply from the source)

This project adopts our company's independently developed YR-9802-15 ceramic crystal stone system, which not only meets the requirements of industrial buildings for high wear resistance, acid rain resistance, and weather resistance, but also presents a delicate and natural sandstone texture. It has become the most textured benchmark factory building in Shunde Intelligent Manufacturing Park.

II. Material Combination Scheme (Yongrong Industrial Ceramic Crystal Beige System)

Core product: Ceramic Crystal YR-9802-15

1.Main color

○ Warm Beige: YR-9802-15-MY (Main Facade)

○ Light gray: YR-9802-15-GY (for plinth, moldings, and basement areas)

2.partial embellishment

○ Industrial Orange: YR-9802-15-OR (logo area, entrance arch)

3.Reasons for material selection

○ Ceramic stone uses a high-temperature calcined colored sand and environmentally friendly resin formula, with a Mohs hardness of 5-7, perfectly resisting acid rain and industrial environmental erosion in Foshan.

○ The warm beige main tone reduces the summer heat island effect, while light gray enhances the three-dimensionality, resulting in an overall warm yet technologically advanced feel.

○ With fine particles and breathable, non-suffocating texture, it is especially suitable for basements and semi-enclosed spaces.

III. Detailed Explanation of Construction Technology (Yongrong Ceramic Crystal Stone Industry's 9 Processes)

1.Substrate preparation: Concrete should be fully cured, with a moisture content ≤8% and a pH ≤10.

2.Clean away dust, oil, and mold release agent.

3.Crack-resistant mortar + alkali-resistant mesh applied in full coat to prevent cracking

4.Apply two coats of flexible putty to level the surface, then sand until the thickness is ≤3mm using a 2m straightedge.

5.Apply one coat of alkali-resistant sealing primer by roller.

6.Apply one coat of ceramic crystal stone intermediate coating (1-1.5mm thick, uniform base color).

7.The ceramic crystal material is applied in two coats (total thickness 2.5-4mm, finished by hand to smooth out grain).

8.Localized hand-drawn or embossed textures create a natural sandstone texture.

9.Apply two coats of water-based matte topcoat by roller (to enhance stain resistance and self-cleaning properties).

Key to construction: The main material must be applied in two thick coats to ensure a dry film thickness of ≥300μm, with full particles and a realistic texture.

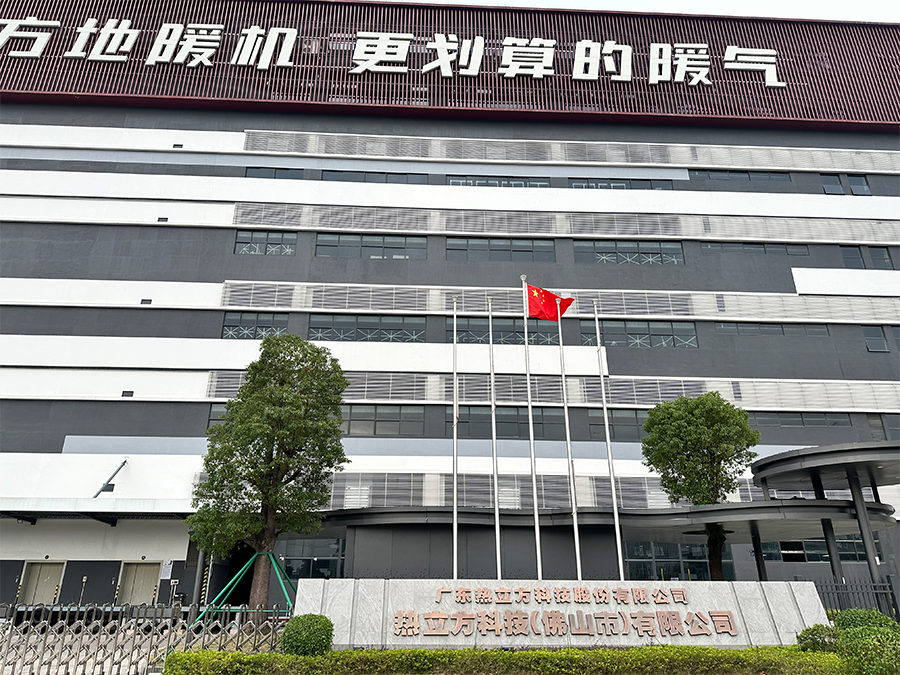

IV. Panoramic View Display

● The warm beige ceramic crystal stone exhibits a delicate and soft sandstone texture under sunlight, resembling a natural yellow sandstone wall from a distance.

● The light gray base and lines are understated and pleasing to the eye, while the industrial orange accents are striking and sophisticated.

● The basement and semi-basement areas use ceramic stone in the same color scheme, completely eliminating the problems of mold and blackening caused by traditional paints.

● After a year of enduring high temperatures and humidity, typhoons, and acid rain in Foshan, the beige color remains warm and new, with no powdering, no sand shedding, and no cracking.

● The park is clean and upscale, and has become a representative of the "most high-quality factory buildings" in Shunde's intelligent manufacturing circle.

V. Core Advantages of Source Manufacturers (Why does HotCube use Yongrong Ceramic Crystal Stone for its entire factory?)

● Specializing in ceramic crystal stone systems for industrial buildings, we have a deep understanding of Foshan's climate, characterized by heavy acid rain and strong ultraviolet radiation.

● The high-temperature calcined colored sand formula of ceramic crystal stone is specially designed for industrial environments, offering superior hardness and weather resistance.

● The entire system is self-produced and self-sold, with 100% consistent colors for primer, intermediate coat, main material, and topcoat.

● Provides a complete, breathable, and mildew-proof solution for damp basement environments.

● With experience collaborating with numerous heat pump and intelligent manufacturing companies, we are familiar with the pain points of industrial plant construction.

● We provide a full range of services from scheme design and sample confirmation to construction guidance.